Facility control system for Jowa Ecublens

For Jowa in Ecublens, the existing facility control system had to be replaced and renewed. In addition to replacing the control system of the existing building equipment, the short implementation and commissioning time was a major challenge for all those involved in the project.

- recording of relevant operating data

- power consumption control

- message configurations directly on the system

- alarm system with freely definable messages and channels

- integration of existing plant components

- datalogging with historical trending

- customer-specific user administration

- desktop and mobile operation options

- interface definitions for third-party equipment

Project description

The renewal of the facility control system is a first modernization step of the customer to make the plant fit for the future. Thanks to years of cooperation, ICS Automation AG was asked to replace the existing control system and replace it with a new system. The previous system was based on obsolete hardware and software, but already processed more than 2000 data points from 15 control systems. After an initial on-site inspection, the new concept was designed with the customer, which included not only a replacement but also the integration of additional control systems. Some control systems were also to be replaced and modernized. Communication between the systems was converted to Profinet and Ethernet to make the system even more flexible. For the control system, the customer's focus was not only on functional requirements but also on expandability by the customer's own personnel. The newly implemented facility control system is therefore based on a Siemens WinCC V7 platform, which was expanded with an Alarm Control Center (ACC). Thus, the system can be independently maintained, configured and expanded by the customer.

Project details

As a result of the modernization, the customer benefits from:

- replacement of obsolete hardware and software

- new network and IT structure

- virtualization of servers & clients

- simplification of the operation

- visualization of the captured values

- integration of local stand-alone HMIs via VNC or Smart@ccess

- new PLC substations instead of direct I/O connection

- defined interfaces for data exchange with substations

- extended 24/7 support

Requirements

- replacement and adaptation of existing functionality

- integration of additional PLCs (total 18)

- integration of > 5'000 historical variables

- definition of alarm classes

- alarming via SMS, email, etc.

- configuration of alarming rules

- ceation of additional trend curves

- alarm suppression for maintenance interruptions

- connecting the machine HMIs

- new network topology (Ethernet) with virtualized clients

- short time slot for commissioning

Scope of supply

- recording of the customer's needs

- concept development

- replacement of facility control system with WinCCV7

- system setup with virtualized clients

- replacement of individual control systems

- communication block for data exchange

- integration of machine HMIs over VNC

- data trend and curves with Historian

- configurable alarming system

- installation and modification on site

- commissioning

- service and support (7/24)

Hardware & control

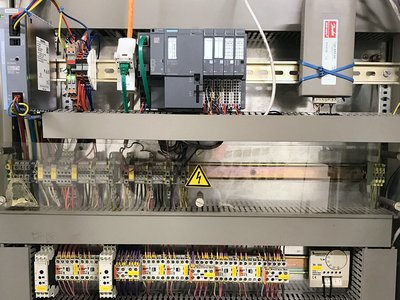

- replacement of several S7-300 PLCs

- connection of EA's with ET200SP

- connection of 18 control systems of different manufacturers

- Siemens WinCC V7 for user interface

- curve trends with WinCC functions

- integration of ACC (Alarm Control Center)

- integration of >5000 historical variables

- network infrastructure via Ethernet / Profinet

We would be pleased to demonstrate our expertise and present our worldwide references to you.

We are at your disposal at any time for a presentation of our skills and show you development possibilities for your business by means of some reference projects. We are convinced that, thanks to our many years of experience in various industries, we combine the necessary skills to accompany you profitably.