Integration maintenance software

Many of our customers work with our process control system and the process visualization every day. By displaying and analyzing all the controlled elements, the user always has an overview of his production processes as well as the status of the plants. However, in addition to topics such as production control, traceability, ERP connection, data acquisition and infrastructure, the high flexibility of our system also allows the integration of third-party equipment, third-party systems or third-party software tools.

This success story describes the integration and connection of a maintenance software. The maintenance software was launched by the customer to organize periodic maintenance and repairs. In order to facilitate the roll-out, existing data should be transferred from the ICS process control system to the maintenance software. This requirement was finally fine-tuned step by step and today offers the following advantages:

- use of the existing data such as element description, element numbers, I/O allocation, etc.

- central entry point for maintenance team via process visualization

- search function for easy location of elements

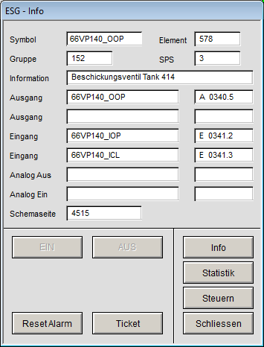

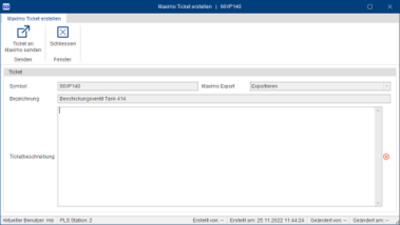

- ticket creation directly from the familiar element window

- direct access to maintenance software from existing control station

- traceability thanks to notification log / audit trail

- advanced production data acquisition

Project description

The web-based maintenance software is connected via a REST API. The data content is serialized as JSON. For the implementation of the service the following interfaces and functions were implemented:

- Creating and updating elements

The process control system imports all elements connected to the system at startup. Based on the configuration, the elements with associated symbols and descriptions are transferred to the maintenance software. If a description changes, the element is transferred again and thus the description is updated automatically. - Create and view maintenance tickets

Via process visualization, maintenace tickets can now be created for all the integrated elements. For this purpose, the already known element windows have been extended. After the input confirmation, the ID and entered description are sent as a message to the maintenance software and a maintenance ticket is created. - Central entry point

Thanks to the integration into the process visualization, the user interface of the maintenance software can now be accessed on every operator station of the plant. In addition, the already well-known process visualization and the element search function integrated into it make it easier to find the desired element.

Requirements

- central access thanks to integration via web control

- use of existing data for maintenance software

- automatic update of changed element descriptions & properties

- simple and automatic import of new elements in case of modifications / extensions

- creation of tickets via the existing visualization

- easy handling and orientation

- audit trail / traceability

- central user administration

Scope of supply

- identification of the customer's needs

- workshop and analysis of possibilities

- interface definition with perspective on further extensions

- creation of the appropriate data structure

- creation of control and operating concept

- extension of ESG window for central entry point

- integration via Web-Control

- testing of the interface with the productive system of the maintenance tool

- preparation of master data

- commissioning

- service & support with remote access

We would be pleased to demonstrate our expertise and present our worldwide references to you.

We are at your disposal at any time for a presentation of our skills and show you development possibilities for your business by means of some reference projects. We are convinced that, thanks to our many years of experience in various industries, we combine the necessary skills to accompany you profitably.